Conveyor Belt Fasteners

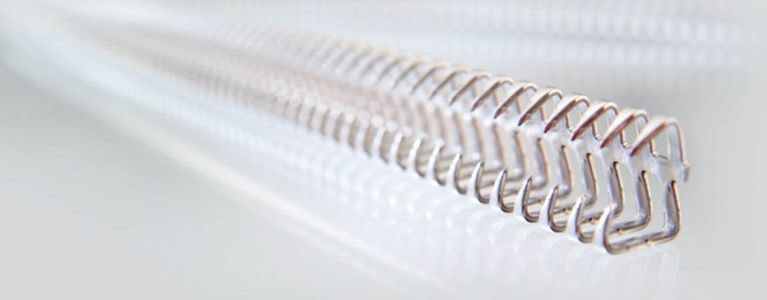

Steelgrip™ Lacing

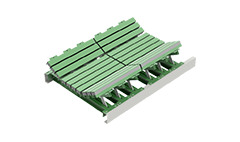

Time-tested and proven dependable, the strength of Steelgrip™ lacing is enhanced due to the common bar, which yields a continuous lacing strip for the width of the belting. Thus, the tension is distributed across the entire belt width.

Steelgrip™ lacing is made from special steel that allows the points to pierce the belt carcass, yet the teeth are designed to enter the belt fabric without cutting the longitudinal strength members of the belting.

Application requires a hammer and gauge pin — no further tools are needed — to assure long life and maximum reliability in lightweight belts.

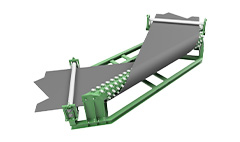

With long lengths for flat conveyor belt applications, Steelgrip lacing is available in eight styles and an almost endless variety of lengths to suit the specific application. The advantage of long lengths is to assure uniform pull across wide belts, distributing the tension of the belt evenly. Steelgrip™ long-length lacing is available from stock in most popular long-lengths up to 1500mm. Special lengths, including continuous strips for extremely wide belts, are also available. Steelgrip™ long-length lacing is specially mounted and shipped in cartons designed specifically for the purpose in order to prevent bending or end damage.

Selecting Steelgrip Lacing Size, Weight & Metal

Steelgrip™ lacing comes in eight sizes for belts from 1.6 to 9.5mm in thickness. The lacing is cross-scored so that it can easily be broken by hand to fit any belt width exactly. Each box includes lacing, a gauge pin, hinge pins, and installation instructions.

Galvanized

Standard for sizes 00, 1, and 7. Good for abrasion utilizing low-carbon steel. Galvanizing provides some resistance to elements. Magnetic and poor chemical resistance.

Carbon Steel

Standard for sizes 15 through 45. Good for abrasion, utilizing low carbon steel which has good forming characteristics that allow easy installation. Magnetic and poor chemical resistance.

Stainless Steel

A nickel chrome stainless steel that offers excellent resistance to fatty acids and wash-down chemicals, also good for mechanical abrasion. Excellent for use where food and sanitation requirements are high. Basically non-magnetic.

FASTENER SELECTION CHART

| PRODUCT SIZE | MIN. PULLEY Ø | KN/M MAX | BELT THICKNESS (mm) |

|---|---|---|---|

| 00 | 25 | 4 | 0 – 1.6 |

| 1A | 38 | 8 | 1.6 – 2.4 |

| 7 | 51 | 9 | 2.4 – 3.6 |

| 15 | 64 | 12 | 3.2 – 4.0 |

| 20 | 76 | 17 | 4.0 – 4.8 |

| 27 | 127 | 18 | 6.3 – 7.1 |

| 35 | 178 | 26 | 7.1 – 7.9 |

| 45 | 229 | 28 | 7.9 – 9.5 |