Case Study

South Flank Plant Conveyor Project Fuels Belle Banne’s WA Growth

Key Statistics

WA

11/05/2021

Description

Established in 2009, Belle Banne Conveyor Products (BBCP) has fast developed a strong reputation as a developer and manufacturer of conveyor equipment, with its products now widely used in Australia as well as in New Zealand, South Asia and other global markets.

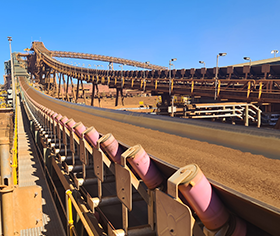

More recently, the company has opened its first WA-based facility in Welshpool, Perth, to better service its growing number of local clients. Among its current Western Australian projects, BBCP is in the final stages of completing the conveyor frame and idler supply for BHP’s South Flank Plant Conveyors .

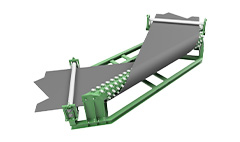

To meet the needs of this large-scale project, BBCP’s in-house engineering, drafting and quality and logistics management teams has supplied over 13,800 conveyor idler frames, 41,000 rollers, 17,000 steel and composite wind guards, and belt handling frames.

Overall, the supply scope has included over 30 roll types and 90 frame types, all which were designed to suit the South Flank Plant Conveyor’s various conveyors belt widths – ranging from 750 mm to 2,400 mm – and material capacities of up to 33,500 tonnes per hour.

A major factor in BBCP being awarded the project was the company’s ability to supply its proprietary Ultraroll™, which makes up the majority of the carry and return idler rollers for the project. These idlers were designed by BBCP in-house with FEA simulations using ANSYS Mechanical to ensure the client’s technical specifications, including infinite frame life, were achieved.

Ultraroll™ features reinforced composite construction of both roller tube and bearing housings and is a key to reducing the weight of traditional idler, helping to achieve weight reductions of up to 60 per cent, compared to standard steel rollers while not sacrificing roller longevity.

A positive flow-on effect of the lighter idler rollers is safer and easier manual handling which is particularly important especially during roll change out. Operational benefits from Ultraroll™ include its low noise certification and being ‘belt-friendly’ (no sharp edges), as well as reducing whole-of-life asset cost.

BBCP’s Ultraroll™ is manufactured in a distinctive pink colour making it instantly recognisable, while also drawing attention to several cancer charities that BBCP has aligned with. A percentage of proceeds from the supply of each idler delivered to South Flank will be donated to national breast, prostate and melanoma cancer research foundations.

BBCP Managing Director, Daniel Weekes, said the South Flank project had provided an excellent launch pad for BBCP’s growth in Western Australia.

“As a company, we’re delighted at being involved with BHP’s South Flank project,” Mr Weekes said. “With our new presence in Welshpool, BBCP can now offer a higher level of local engineering, design drafting and technical support on the ground in Western Australia.“Our WA team is steadily growing with a number of recent local appointments, and we look forward to continue delivering a high level of service and support to South Flank along with other projects in the region.”