Conveyor Belt Cleaners

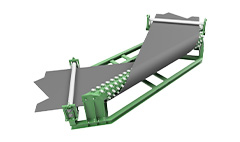

U Secondary Belt Cleaners

The original Belle Banne® U Belt Cleaner is unmatched for superior cleaning efficiency – especially in tough applications requiring the removal of wet and sticky material. The patented U shaped blade conforms to the belt allowing the carbide tips to scrape stubborn materials off the belt while the rubber backing squeegees wet materials. The dual spring tension system maintains low, uniform blade pressure across the entire belt width. The U shaped blade of the U Belt Cleaner and offset pole intensify cleaning power in the material carrying centre of the belt. The U Belt Cleaner is unbeatable as the final cleaner in a complete cleaning system.

Teamed with a Belle Banne® primary cleaner, the Belle Banne® U Belt Cleaner delivers results that are unmatched for cleaning performance and efficiency.

UNIQUE U SHAPE

The Belle Banne® U Belt is “Unique” in its shape. The U-shaped blade maintains maximum pressure in the centre of the belt where the majority of the material builds up.

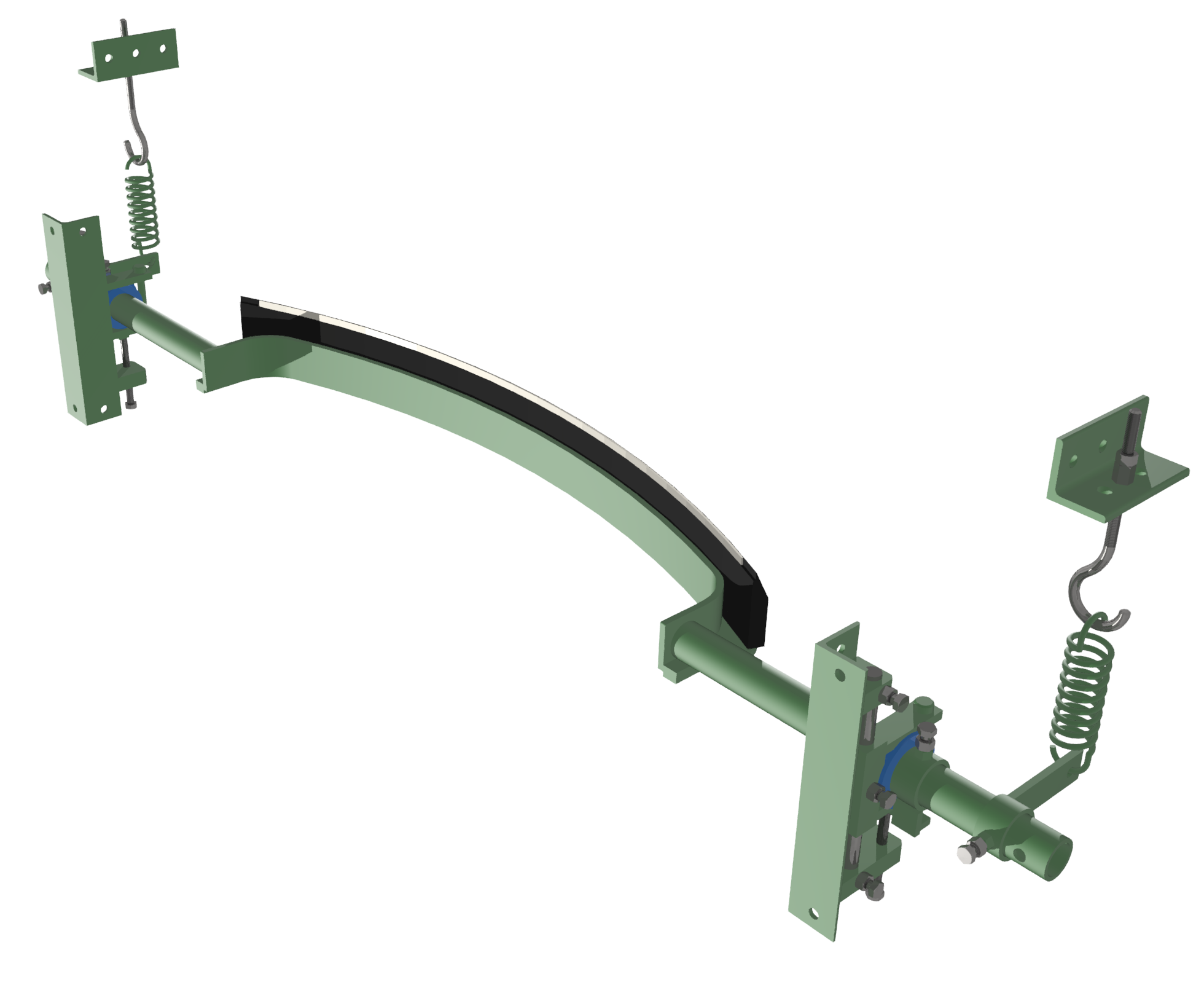

EASY BLADE REPLACEMENT

The Cartridge blade means that blade removal and replacement can be achieved in just minutes.

SIMPLE TENSION CHECK

The spring adjustment system makes for a quick visual check to ensure the Belle Banne® U Belt Cleaner is suitably tensioned. Look for a 1-2 mm gap in the spring coils.

BLADE STOP

The cleverly designed blade stop ensures that when the blade has been fully exhausted that the cleaner stops travelling and prevents unnecessary belt or cleaner wear.

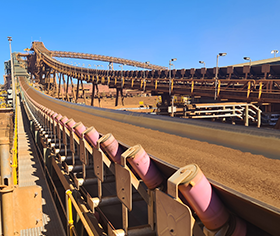

Coal, Iron Ore, Hard Rock, Heavy Metals, Sand and Gravel, Recycling, Power Generation and Steel Mills. Contact BBCP for more information on your application.

| BELT WIDTH (mm) |

POLE LENGTH (mm) |

POLE DIA (mm) |

ITEM CODES | |||

|---|---|---|---|---|---|---|

| MILD STEEL | STAINLESS STEEL | |||||

| 450 | 1450 | 48 | 140001 | 145001 | ||

| 600 | 1600 | 48 | 140002 | 145002 | ||

| 750 | 1750 | 48 | 140003 | 145003 | ||

| 900 | 1900 | 48 | 140004 | 145004 | ||

| 1050 | 2050 | 48 | 140005 | 145005 | ||

| 1200 | 2600 | 60 | 140006 | 145006 | ||

| 1400 | 2800 | 60 | 140007 | 145007 | ||

| 1500 | 2900 | 60 | 140008 | 145008 | ||

| 1600 | 3000 | 60 | 140009 | 145009 | ||

| 1800 | 3200 | 76 | 140010 | 145010 | ||

| 2000 | 3400 | 76 | 140060 | 145060 | ||

| 2100 | 3500 | 76 | 140011 | 145011 | ||

| 2400 | 3800 | 76 | 140012 | 145012 | ||

| 3000 | 4400 | 76 | 140013 | 145013 | ||