Conveyor Belt Fasteners

Staplegrip™ Preset Lacing

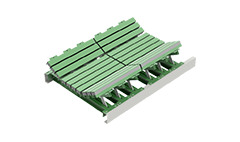

Staplegrip™ belt fasteners are unique compared to conventional lightweight belt fasteners, because the staples are clinched 90 degrees to the direction of the pull of the belt. Therefore, it is virtually impossible for the staple to open under load.

Our Staplegrip™ belt fasteners are also unique. While other brands may be rectangular, with their narrow dimension in line with the pull of the belt, Staplegrip™ staples are oval-shaped with smooth, rounded edges. This design feature reduces the possibility of the staple damaging belting fabric.

Traditional Staplegrip™ Lacing

Traditional Staplegrip™ lacing has been an industry standard for years. To install manually, a dispenser allows you to insert the staples smoothly into the fastener strip using the field lacing tool to align the belt fastener across the belt. A light hammer and punch then drives the staples through the belt and clinches the fastener.

Staplegrip™ Preset Lacing

Staplegrip™ Preset Lacing can only be used in hammer driver fixtures. Available in the popular 62, 125, and 187 sizes that fit belts 1.6 to 6.4mm. The lacing is cross scored so it can be easily broken by hand to fit any belt width exactly.

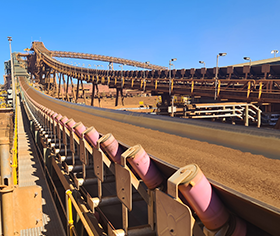

Belle Banne Conveyor Products supplies a complete range of conveyor maintenance products. Categories of mechanical fasteners supplied are bolt solid plate, rivet hinged, staple and lacing fasteners.

To ensure a complete, worry-free service, a range of tools for fastener installation is available, including belt cutters, belt skivers and clamps.

FASTENER SELECTION CHART

| PRODUCT SIZE | MIN. PULLEY Ø | KN/M MAX | BELT THICKNESS (mm) |

|---|---|---|---|

| 62 | 50 | 17 | 1.5 – 3.2 |

| 125 | 75 | 28 | 3.2 – 4.8 |

| 187 | 100 | 35 | 4.8 – 6.4 |