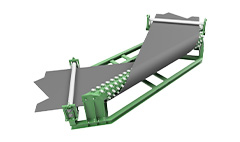

Conveyor Belt Rollers

Steel Conveyor Rollers

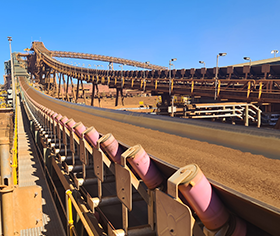

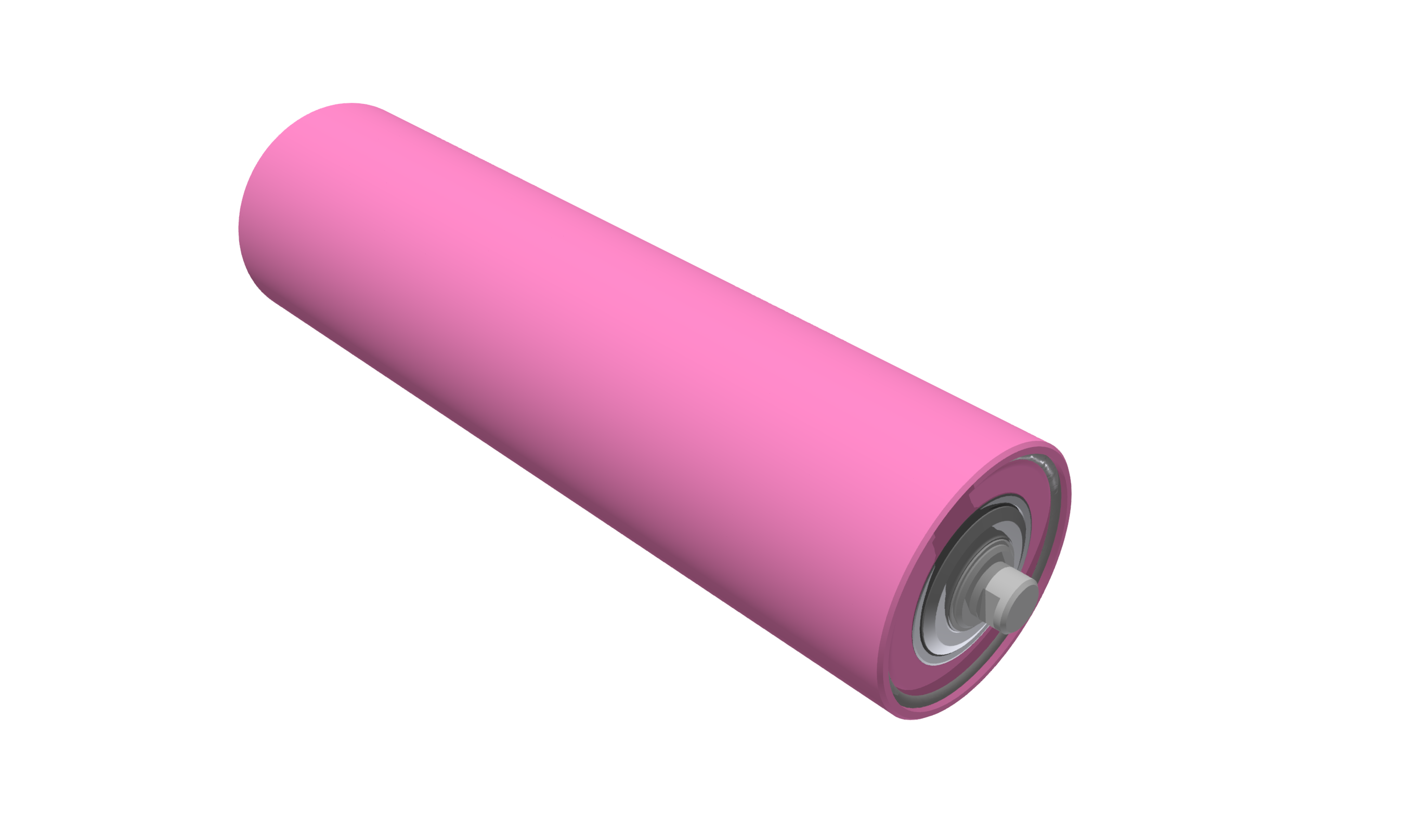

BBCP steel rollers are a conventional, heavy duty, reliable roller option with steel bearing housings and a steel shell. These are welded together, which ensures there is no risk of housings separating over time from factors including heavy loading, moisture ingress and thermal expansion. The bearing housing is designed in a way that ensures that, in the event of shell failure, the traditional sharp edge that can “pizza cut” the belt doesn’t exist.

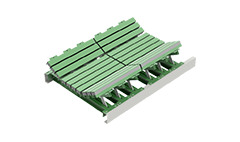

BBCP steel rollers are supplied with 2RS NSK greased-for-life bearings and include double-sided triple-labyrinth seals, plus a dust seal which also includes a labyrinth seal. Steel rollers are suitable for heavy duty applications, in materials handling applications ranging from the smallest quarries up to major mining operations (iron ore, hard rock, black coal, etc,). Ideal for heavy duty applications, steel rollers are heavier than the alternatives, but are robust enough to handle the roughest treatment during storage, transport, installation and operation. Steel rollers are suitable for underground applications. They are powdercoated as standard and can be coloured to your choice. Other coating options, which can improve shell life include:

- Inorganic Zinc Silicate Primer

- Galvanising

- Rubber Lagging

- FRAS Rubber Lagging

- Ceramic Lagging

- Polyurethane Lagging

Features & Benefits

- Available in shaft diameters from 20mm to 60mm

- Available in shell diameters from 88.9mm to 193.7mm

- Total Indicated Runout (TIR) = 0.65mm maximum up to 750mm rollers and 0.000867 x L for >750mm rollers

- Maximum out-of-balance tolerance of 0.028Nm

- Suitable for underground applications