Conveyor Belt Cleaners

R Secondary Belt Cleaners

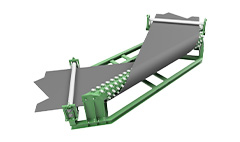

The Belle Banne® R Belt Cleaner has been a successful secondary cleaner for over 30 years. Designed specifically for use in reversing applications, it can be teamed with a Belle Banne primary cleaner and has proved effective in maintaining a clean conveyor belt across diverse applications.

Ideally positioned just back from the head pulley, the Belle Banne® R Belt Cleaner is compact enough to fit in most chute applications and sits close enough to the pulley to ensure the material fines are directed back into the regular material flow.

The R Belt Cleaner is ideal on reversing belts and conveyors which runback. Available in all sizes to suit your belt width, and in a range of materials to optimize life and performance.

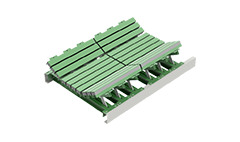

SEGMENTED BLADES

The R Belt cleaner consists of individual 150 mm segmented blades, each one mounted to a durable rubber cushion. Separate blades ensure constant blade to belt contact on uneven surfaces, guaranteeing maximum cleaning performance.

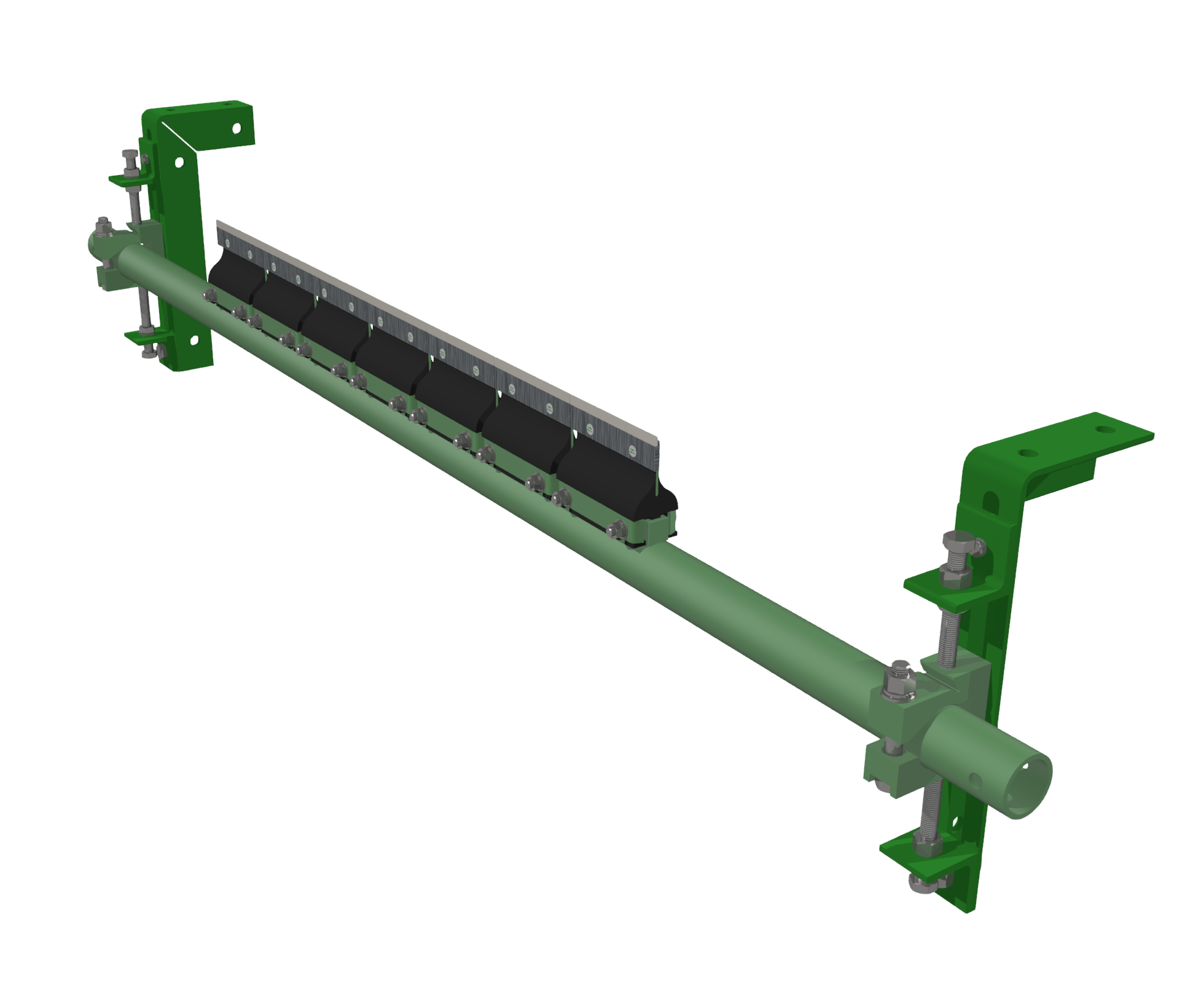

LONG LASTING TUNGSTEN

Belle Banne® has long been the leader in its class when it comes to tungsten. Our tungsten has a proven track record for consistent wear and long blade life.

No other tungsten blade comes close.

SYMMETRICAL CUSHION DESIGN

The R Belt Cleaner’s symmetrical cushion design ensures the R Belt Cleaner tips meet the belt at 90 degrees to maximize cleaning performance regardless of the direction of travel of your conveyor. Optimally positioned off the head pulley, the Belle Banne® R Belt Cleaner is a compact design allowing cleaned fines to return to the material flow.

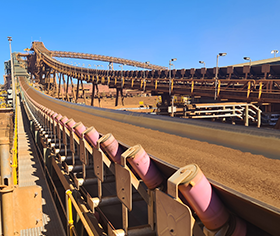

Coal, Iron Ore, Hard Rock, Heavy Metals, Sand and Gravel, Recycling, Power Generation and Steel Mills. Contact BBCP for more information on your application.

| BELT WIDTH (mm) | BLADE WIDTH (mm) | POLE LENGTH (mm) | POLE DIA (mm) | ITEM CODES | |||

|---|---|---|---|---|---|---|---|

| MILD STEEL | STAINLESS STEEL | ||||||

| 450 | 450 | 1450 | 60 | 130001 | 135001 | ||

| 600 | 600 | 1600 | 60 | 130002 | 135002 | ||

| 750 | 750 | 1750 | 60 | 130003 | 135003 | ||

| 900 | 900 | 1900 | 60 | 130004 | 135004 | ||

| 1050 | 1050 | 2050 | 60 | 130005 | 135005 | ||

| 1200 | 1200 | 2600 | 60 | 130006 | 135006 | ||

| 1400 | 1400 | 2800 | 73 | 130007 | 135007 | ||

| 1500 | 1500 | 2900 | 73 | 130008 | 135008 | ||

| 1800 | 1800 | 3200 | 73 | 130009 | 135009 | ||

| 2100 | 2100 | 3500 | 73 | 130010 | 135010 | ||

| 2500 | 2400 | 3900 | 73 | 130011 | 135011 | ||

| 3000 | 3000 | 4400 | 73 | 130012 | 135012 | ||