Conveyor Idlers

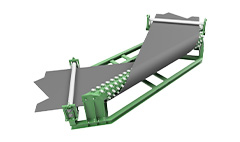

Carry Tracking Idlers

BBCP carry trackers are engineered and fabricated to exceed industry standards and/or customer specifications. Manufacturing techniques include CNC laser cutters and robotic welding. The combination of high-tech manufacturing equipment, AS1554.1 SP welding and our high-quality management/assurance systems ensures all carry trackers set a benchmark for tolerance and quality levels.

BBCP carry trackers are designed to provide belt tracking on the carry side of the belt, without the use of servo rollers, which are a major contributor to belt edge damage when used on carry-side belt trackers. The conical design of the wing rollers creates differential roller face speeds that pivot the frame and steer the belt back towards the conveyor centreline. The carry tracker has a compact design, is maintenance-free, easy to install, and is suitable for single or reversing belts.

BBCP carry trackers are supplied galvanised as standard, with powder coated frames available if required. They are available to suit belt widths from 450mm up to 3000mm and can be designed and supplied to suit any belt width or roller configuration. A variety of idler frame types and sizes are held in stock. Contact us for more information.

| Belt (mm) | Item Code | Description | Mounting Dimensions (mm) |

| 1050 | 711001 | Belle Carry Tracker Idler Set – 1050 | 1300 |

| 1200 | 711002 | Belle Carry Tracker Idler Set – 1200 | 1450 |

| 1400 | 711003 | Belle Carry Tracker Idler Set – 1400 | 1700 |

| 1500 | 711004 | Belle Carry Tracker Idler Set – 1500 | 1800 |

| 1600 | 710005 | Belle Carry Tracker Idler Set – 1600 | 2000 |

| 1800 | 710006 | Belle Carry Tracker Idler Set – 1800 | 2200 |

| 2000 | 710007 | Belle Carry Tracker Idler Set – 2000 | 2400 |

| 2200 | 710008 | Belle Carry Tracker Idler Set – 2200 | 2600 |