Custom Solutions & Restoration

Outrigger Pads Australia

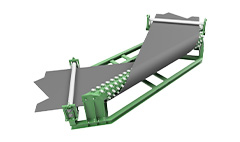

In the world of heavy machinery, safety and stability are paramount. Crane operators and construction professionals know that ensuring a stable base is crucial for the success of any project. That is where outrigger pads, often referred to as crane outrigger pads or crane pads, play a vital role. These unassuming pieces of equipment provide the support needed to keep cranes steady and safe during lifting operations.

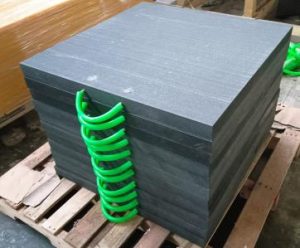

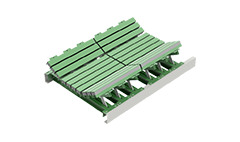

BBCP Outrigger Pads are solid blocks of UHMPWE composite material that are used to distribute the weight of equipment over a greater surface area. Outrigger pads are typically used on cranes, aerial work platforms and other heavy machinery to prevent them from sinking into the ground or damaging surfaces. They are typically placed beneath the crane’s outriggers, which are the extendable arms or legs that support the crane’s weight and prevent it from tipping over during lifting operations. Whether you’re working on a bustling construction site or tackling a delicate lifting operation, outrigger pads are a dependable partner, ensuring your crane stays steady and secure. As the foundation of crane stability, these unassuming pieces of equipment are a testament to the importance of the little things in heavy machinery operations. Our Outrigger pads are available in a variety of shapes and sizes which can also be modified based on customer requirements. Plus, they’re rust-free and easy to handle.

Benefits of Using Outrigger Pads

Enhanced Safety: The primary benefit of using crane outrigger pads is the increased safety they provide. When a crane’s outriggers are adequately supported by these pads, the risk of tipping over is significantly reduced. This is especially crucial when working in challenging environments or adverse weather conditions.

Load Distribution: Crane pads help distribute the weight of the crane and the load it’s lifting over a larger surface area. This prevents the ground from becoming compacted or damaged, which is essential for preserving the integrity of the work site.

Versatility: Crane pads are designed to be versatile. They can be used on a wide range of surfaces, including soil, concrete, gravel, and asphalt. This adaptability makes them an invaluable tool for construction and crane rental companies.

Easy Transportation: Most outrigger pads are lightweight and easy to transport, allowing for quick and convenient setup at different job sites. This mobility saves time and resources, making them a cost-effective solution.

To learn more about pricing and customization options, reach out to BBCP directly at info@bbcp.com.au

Frequently Asked Questions

What size crane pads do I need for my crane?

The size of the outrigger pads you need depends on the size and weight of your crane, as well as the ground conditions you’ll be working on. It’s essential to consult your crane manufacturer or a qualified engineer to determine the appropriate size and load-bearing capacity for your specific crane model.

Are all crane outrigger pads made of the same material?

No, outrigger pads come in a variety of materials, including HDPE, wood, and composite materials such as UHMPWE composite material. The choice of material depends on factors like load capacity, environmental conditions, and personal preference. HDPE outrigger pads are popular due to their durability and resistance to moisture and chemicals.

Can outrigger pads be used on soft or uneven ground?

Yes, crane outrigger pads are specifically designed to provide a stable base on soft or uneven ground. They prevent the outriggers from sinking into the ground and ensure the crane remains stable during operations.

Are outrigger pads reusable?

Outrigger pads are generally reusable, but their lifespan depends on factors such as the material used, the load they bear, and the care taken during handling. Regular inspection is crucial to ensure they remain in good condition and damage-free.

Do I need to follow any safety guidelines when using outrigger pads?

Yes, safety is paramount when using crane pads. Following the manufacturer’s guidelines for proper placement and usage is essential. Always ensure that the pads are on a level surface and that the outriggers make full contact with the pads. Regularly inspect the pads for wear and damage and replace them as needed.